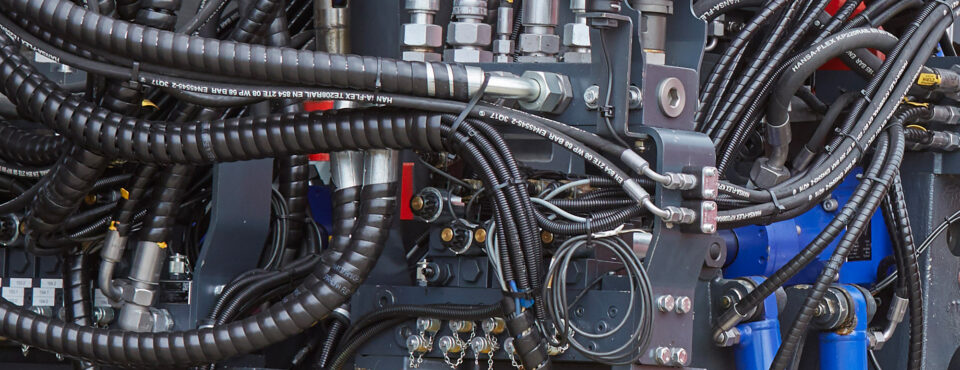

Hose fittings for hydraulics

The fittings designed and manufactured by HANSA‑FLEX are perfect for use with the appropriate hose type. They guarantee a safe and leak-free connection. The range includes all commonly called for nominal diameters and connection types and complies with international standards (BS, SAE, DIN and NF). The fittings are zinc-nickel coated and meet the highest requirements for durability and corrosion resistance.

Press fittings from hansa‑flex

Press fitting systems and solutions for self-assembly

Press fittings for medium- and high-pressure applications

For standard applications in medium- and high-pressure environments, we offer an extensive range of crimping ferrules and hose nipples with metric, UNF, NPT and imperial connecting threads, SAE flange heads and other flange systems. In addition to the generally quicker to assemble no-skive crimp ferrules in which the sleeve is pushed over the unpeeled hose and then crimped, the HANSA‑FLEX online shop also has hose fittings for braided hoses with skive crimp ferrules up to a nominal size of DN 76.

Interlock hose fittings with pull-out protection

To ensure a safe connection between hose and fitting, even under extreme loads and high pressures up to 500 bar, HANSA‑FLEX offers a wide range of interlock fittings up to a nominal size of DN 50 as a system solution with pull-out protection. The inner and outer layers of the hose are peeled (double skive) to allow the crimp nipple to achieve a highly effective positive fit with the hose and the fitting. The loads on the elastomer in the area of the crimping are optimised, which extends the service life of the hose line.

Special fittings made-to-measure

In addition to standard crimp fittings, we design and manufacture special fittings for specific fields of use in all diameters and even large series production to the customer’s individual specifications. Our experts provide comprehensive advice taking into account all the aspects of the whole system to arrive at the optimum solution. Then we manufacture the fittings in our production centre at Dresden-Weixdorf to the highest precision.

Hose fittings from the system provider hansa‑flex

HANSA‑FLEX considers product quality to be extremely important because the quality of the fitting is crucial to the performance of the hose line.

Maximum performance

Every fitting is perfectly matched to the hose and thus offers the highest protection against leaks.

Comprehensive service

All fittings are available individually. We are also delighted to supply them fitted to hose lines.

Maximum safety

Extensive tests ensure the functional capability of the fittings up to 500 bar.

Excellent corrosion protection

Thanks to a zinc-nickel coating, the press fittings are resistant to red rust for 1,200 h.

Sicher, leckagefrei und zuverlässig

- Erfüllung aller Normen und internationalen Standards

- Excellent compatibility with other components

- Designed for high pressures, temperatures and loads

- Versatility through a rich variety of product solutions

- Excellent availability thanks to our own production facilities and dealer network

- Up to 1,500 h corrosion resistance for non-deformed items

Hose fittings for all applications

Fittings for extreme conditions of use

Extreme applications and the highest pressures require special solutions. HANSA‑FLEX crimp fittings for elastomeric and thermoplastic hoses cover the extremely high pressure range and offer a reliable and safe solution for applications involving high pressures in industrial and mobile hydraulics, such as lifting platforms, agricultural and construction machinery.

- Crimp fittings for dynamic loads and high pressures

- Suitable for elastomeric and thermoplastic hoses

- Safe and durable systems with components designed to work perfectly together

Fittings for low-pressure push-on hoses

With push-on fittings, the hose is simply pushed onto the push-on nipple, which fixes it in place. There is no need for time-consuming preparation of the hose because, unlike high-pressure hoses, they can be cut to length using simple cutting tools instead of cutting machines.

- Push-on fittings in brass

- Simple assembly without special tools

- Ideal for low-pressure applications

Easy to install screw fittings

Screw fittings are recognised for their ease of assembly. The ferrule is screwed onto the hose and then the nipple screwed into the connection piece to create the required connection. These screw fittings are normally assembled without special tools and can be reused.

- Ease of manufacture of hose lines

- No special tools such as hose presses are required

- The fitting can be dismantled and reassembled

The wide hansa‑flex fittings range:

As a one-stop partner, we offer a diverse range of crimp and screw fittings in zinc-nickel coated steel, stainless steel and plug-in fittings in brass.

- Straight hose fittings

- Elbow fittings with elbows (45°, 90° and 180°)

- All commercially available nominal diameters and individually manufactured solutions

- Many types of connections (metric, inch, BSP, UNF, NPT, JIS, SAE)

- High-strength fittings up to 500 bar tested to 2,000,000 impulses

These topics may also be of interest to you

Customised assembly

We preassemble customised hydraulic hose lines from samples and to suit customer specific requirements for low, medium and high-pressure applications…

Find out moreHydraulic hoses

Hydraulic hoses transfer fluid safely through the system. Their flexibility means they need very little installation space. The HANSA‑FLEX range includes elastomeric…

Find out moreAdapters

Adapters create a safe and leak-free connection between components with differing thread types. HANSA‑FLEX offers an extensive portfolio of hydraulic adapters, such…

Find out more