Inspections of lifting platforms and loading bridges

Powered and hand-operated lifting platforms, yard ramps and loading bridges must be inspected at least once a year for their safe condition by a suitable expert. The operator is responsible for performing the inspection. The trained experts at HANSA‑FLEX perform the regularly prescribed inspections of this equipment in accordance with DGUV including documentation in accordance with the German Industrial Safety Act (BetrSichV).

Recurring inspections

The manufacturer performs the inspection before the component is brought into first use. The system operator is responsible for the subsequent professional inspections at regular intervals. The officially authorised persons for the inspection of lifting

Inspection of loading bridges and yard ramps

We inspect your loading bridges, truck ramps, channel ramps, yard ramps and mobile loading ramps and ensure that all the safety-related requirements of DGUV Rule 308-002 (formerly BGG 945) are fulfilled at the time of inspection.

- Visual inspection and function test including documentation

- Inspection of loading bridges, truck, channel and yard ramps

- Compliance with all the requirements of standard DIN EN 1398

Inspection of lifting platforms

The suitably qualified employees at HANSA‑FLEX have extensive experience with lifting platforms and assist you with their know-how and practical support with the regular inspection of your equipment in accordance with the legally prescribed requirements.

- Visual inspection and function test including documentation

- Inspection of lifting work platforms, loading platforms, tilting and vehicle lifting platforms

- Performed in accordance with DGUV Rule 108-006 (formerly BGR 233)

Hansa‑flex services offer all these advantages

With HANSA‑FLEX, experienced specialist personnel perform every inspection. They are qualified as officially authorised persons for inspecting lifting platforms, loading bridges and yard ramps.

Qualified experts

Authorised persons for lifting platforms and loading bridges perform the inspections.

No compromise on safety

Ensure compliance with all the requirements of the German Industrial Safety Act.

Comprehensive support

Preparation of mutually agreed inspection plans and the performance of maintenance services

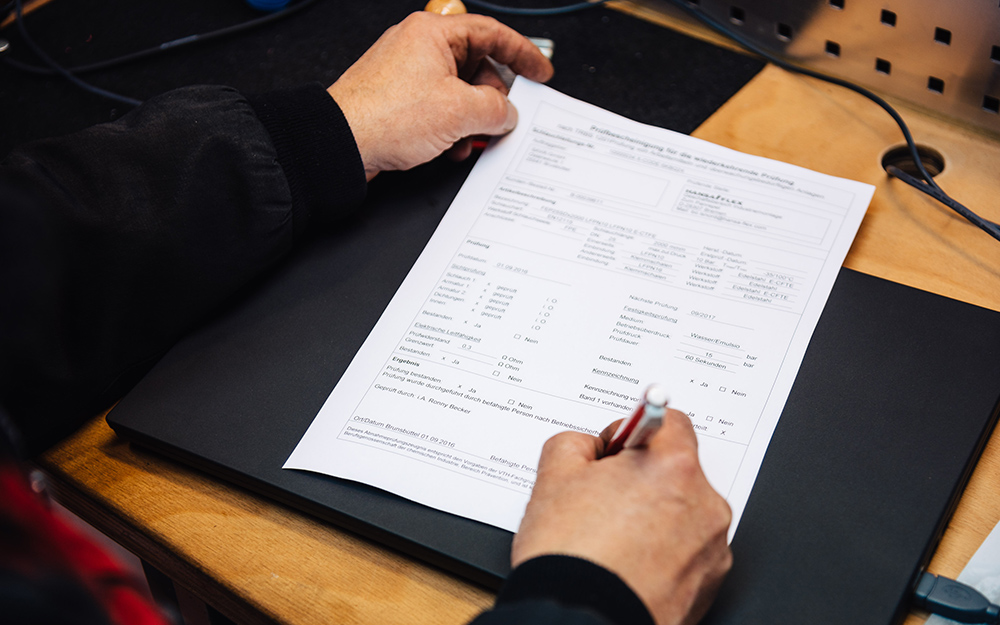

Clearly documented

Preparation and provision of inspection documentation in accordance with the legal requirements.

This is how the annual inspection works and what is inspected

- Inspection workflow

- Documents

- Basic unit

- Fluid technology

- Control system

- Item 1

Our procedures

In addition to the visual inspection and function test, a properly conducted, complete inspection also includes a check of the documents associated with the equipment. Any defects found as part of the inspection are recorded in the documentation. The inspection also determines whether the equipment is ready for operation or whether it must be inspected again after rectification of the issues. After successful performance of the inspection, the date for the next regular inspection is noted in the inspection log. Then the equipment receives the inspection certification mark. This serves as confirmation for the operator and the user that the equipment meets all the legal requirements for its safe operation.

- Item 1

The following documents and certificates are check

The documents are examined briefly before the visual inspection and function test. In addition to checking that the documents are present, we also confirm that the documents and markings are complete and correct.

- Inspection log

- Identification plate / CE marking

- Operating instructions

- Final acceptance inspection record (ramps)

- Load capacity sticker (lifting platforms)

- Item 1

The basic unit is thoroughly tested

Wear of the components on the basic unit of lifting platforms, loading bridges and yard ramps is a natural consequence of regular use. We check to see that the following components are working correctly:

- Frame/bearings

- Pins/fastenings

- End-stop buffers and pins/suspensions (ramps)

- Wheels/undercarriage and safety devices (ramps)

- Wheel stopper, axle play detector and step protection (lifting platforms)

- Item 1

The fluid technology components are also inspected

Some components in hydraulic and pneumatic systems direct the fluid and use it for various functions. They are visually inspected and tested as part of the regular inspection.

- Power unit and lifting cylinder/piston rod

- Pipelines and hose lines

- Extension cylinders/piston rods (ramps)

- Oil types, condition, quantity and the emergency lowering device (lifting platforms)

- Condition and sealing performance of the pneumatics (lifting platforms)

- Item 1

These components are tested in the control system

The control system is a key component of equipment and undergoes just as exacting and comprehensive inspection as the structural components for transferring and controlling forces. The following control elements are inspected or tested:

- Emergency stop switch

- Protection against unintentional switching on

- Command devices

- End switch (ramps)

- Light barriers and lifting/lowering/move to engage latches (lifting platforms)

Inspections before bringing into first use

An inspection must be carried out before the bringing into first use of lifting platforms and loading ramps to check for faulty construction and installation. The manufacturer or the manufacturer and the operator perform the inspection, depending on the s

Inspections that are the manufacturer’s responsibility

The inspection before bringing into first use comprises the pre-inspection, construction inspection and final acceptance inspection and is the responsibility of the manufacturer. In the course of this inspection, a check is made to see that the equipment meets the essential health and safety requirements and that it will not endanger persons during its envisaged period of use. In addition, the manufacturer must document all steps in the inspection. Then the equipment receives the required CE marking necessary for its operation.

Inspections that are the responsibility of the operator

If a lifting platform or ramp has not been delivered as ready for operation, the operator must check that it is ready for operation, including installation and equipment, before it is brought into first use. The operator is also responsible for performing extraordinary inspections and the regular 12-monthly inspections. All inspections must be carried out by suitably qualified persons and properly documented.

These topics may also be of interest to you

Inspections

Hydraulic systems work extremely hard. Regular inspections are therefore obligatory in order to ensure reliable and safe operation of systems…

Find out moreRepair and overhaul

Hydraulic systems are continuously under load and therefore wear will eventually occur on their components. If this is not detected…

Find out moreFluid management

Oil care is a key factor in ensuring trouble-free operation of hydraulic systems and plants. Contaminants in the fluid can…

Find out more