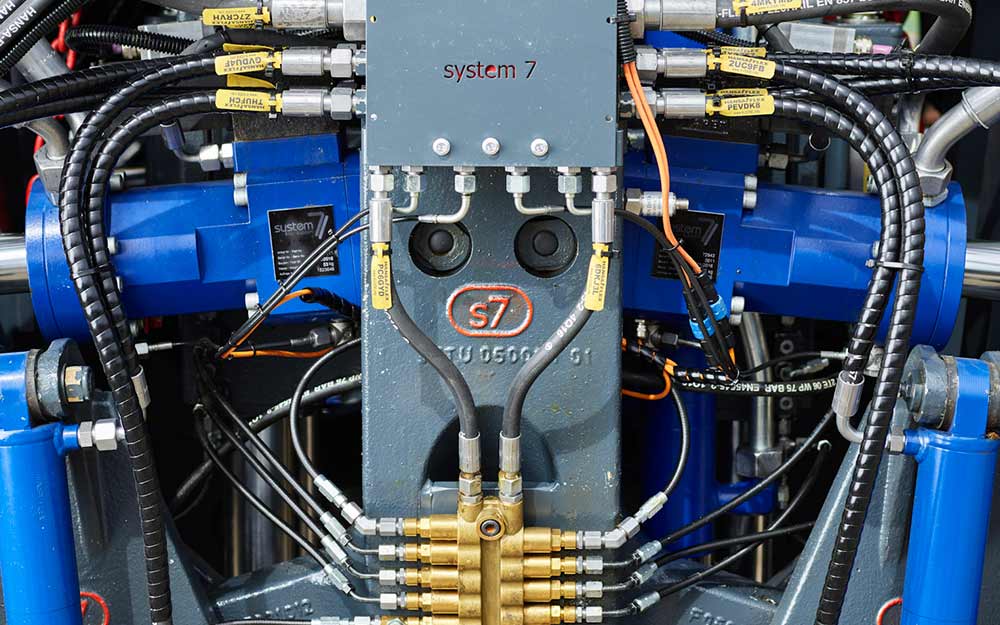

The track construction machine manufacturer system7 eliminates the disadvantages of conventional machines for track and track bed maintenance with a fully hydraulic drive. As a system partner, HANSA-FLEX not only supplied all the hydraulic hose lines.

12.03.2024

Pressure instead of rotation

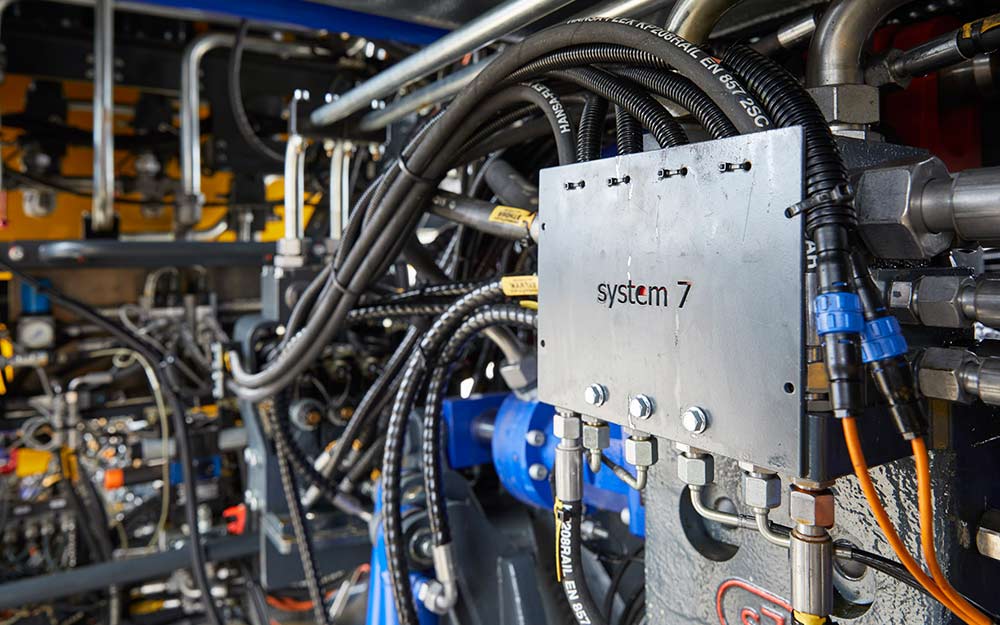

Less wear and tear, reduced noise, increased precision and improved quality assurance: with a fully hydraulic drive system7, the Austrian manufacturer of track construction and maintenance machinery, has eliminated the disadvantages of conventional machines when it comes to the maintenance of railway track and roadbed. As the system partner to the company HANSA‑FLEX not only supplied all the hydraulic hose lines, but also assembled the hose lines and pipes on site at system7.

In rail traffic the track plays a central role: not only does it have to guide trains safely, but also to absorb the resulting forces and transfer them to the sub-structure via the sleepers and hard-core bed. It all sounds very simple, but in view of the 22.5 tonne axle load which is permitted in Europe this is anything but trivial, because the forces that are generated are huge. A force of 110 kilonewtons acts on a contact surface of only 3 cm² between wheel and rail. The consequence is that the track geometry, i.e. the horizontal (direction) and vertical (height) alignment of the tracks and points deteriorates over time.

Machine tamping

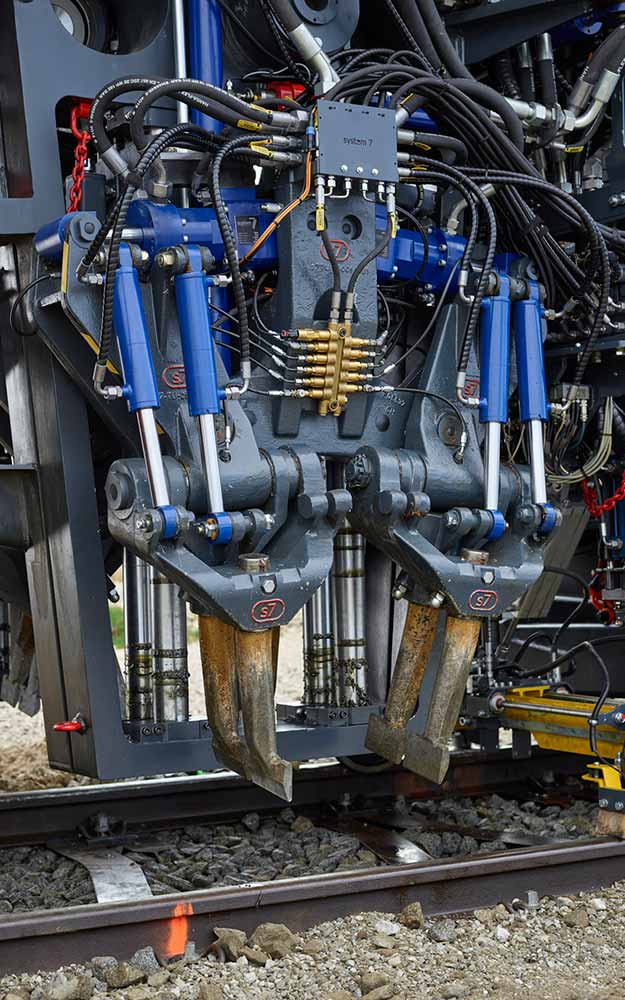

Regular maintenance work is required in order to correct these geometric track errors. For this purpose the track and the points are raised and then realigned with geometrical correctness. At the same time the hard-core bed is compacted in order to stabilise the realigned track geometry. In technical terms, the track is ‘tamped’. In the early years of rail, maintenance workers had to carry out the tamping manually with a winch, ballast fork and tamping hoe, but for the past 80 years this task has been carried out by machinery. For this purpose track tamping machines are equipped with lifting and aligning tools as well as vibrating tamping tines, which penetrate the gravel track bed and compact and stabilise the gravel.

Fast start, fast stop

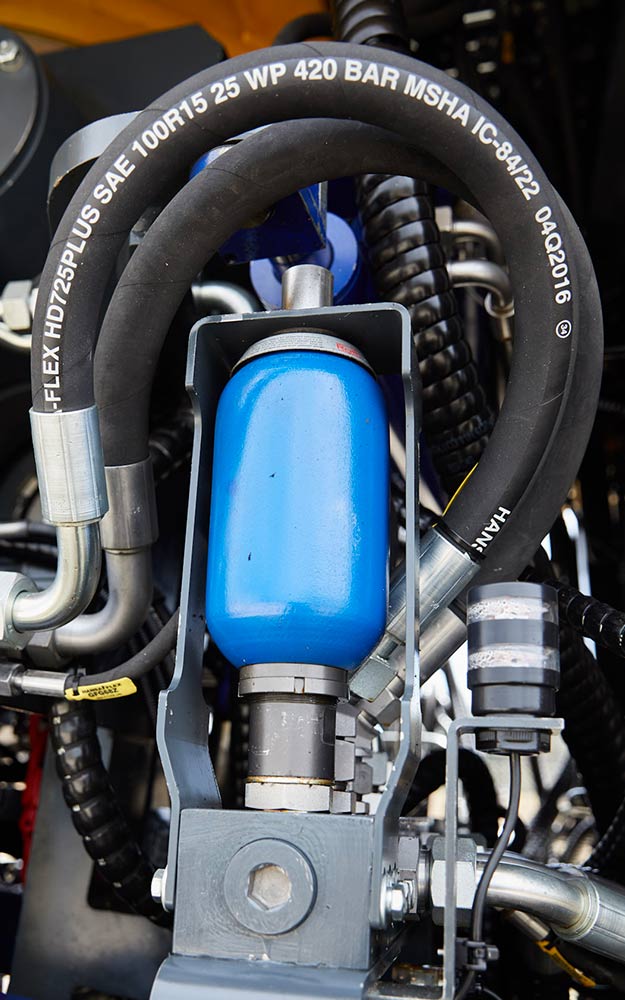

Conventional tamping machines work with an eccentric shaft, which sets the tamping tines into sinusoidal oscillation. “The large number of rotating and therefore wear-intensive parts, the continuous noise emission as well as the rigid and therefore inflexible control system caused us to break new ground with our ‘Universal Tamper 4.0’ development”, explains system7 CEO Hansjörg Hofer. The core of the machine, which has been awarded 20 different patents, is the low-noise tamping assembly with its fully hydraulic drive. The vibration and adjustment operations are implemented hydraulically. The advantage is that the vibration does not begin until shortly before the tamping tines reach their operating position in the ballast bed. “Modern proportional valves are able to control large quantities of oil in a very short period of time. A tamping operation only lasts 1.5 seconds. Such start-stop controls wouldn’t be possible at all with rotating vibration shafts”, states Hofer.

Less noise, greater flexibility

Track construction work is generally carried out at night, in order to avoid affecting rail traffic. The fully hydraulic drive system greatly reduces the noise which is generated, thus enabling operations at night even in urban areas. The system also offers further benefits. One example is that the positioning cylinders which control the tamping tines are fitted with non-contact displacement sensors. Further sensors measure the pressure in the hydraulic cylinders. “This enables us to adapt the frequency, vibration and opening width dynamically to the individual conditions”, reports Hofer.

Extreme precision

The sensors enable system7 to measure and record the compaction density of the ballast. Providing insight into operating practice Hofer adds: “Knowledge of the condition and hardness of the ballast along the track means that railway operators can implement new concepts such as predictive maintenance, while avoiding excessive wear and tear before it even starts by taking the appropriate action”. The lifting and alignment of the track are also implemented hydraulically. The operations are controlled by a newly developed software programme which networks a large number of sensors, hydraulically controlled circuits and laser scanners. It provides the operator with predictive controls of the type applied in the navigation unit of the Airbus. “The Universal Tamper automatically calculates the correction values for the layout of the track. It isn’t enough simply to concentrate on a specific area. Instead the entire section of track has to be taken into account, because otherwise the result could be periodic track errors.”

The decisive factor was that HANSA‑FLEX gave us very good advice from the very first hour and complies with all the standards relevant to rail vehicles, such as EN 45545-2!

Hansjörg Hofer

CEO system7

Consulting, assembly, service

HANSA‑FLEX is responsible for a large part of the hydraulic components. “The decisive factor was that from the very beginning HANSA‑FLEX provided us with professional advice, while meeting all the relevant standards which apply to rail vehicles, such as EN 45545-2”, states Hofer. System7 consciously opted for a system partnership which goes well beyond pure supply operations: “We wished to benefit from our partner’s many years of experience, and therefore also outsourced the assembly operations”.

Technicians from the HANSA‑FLEX branch in Wels were regularly on site in order to fit the hoses and pipes for the prototype of the Universal Tamper. “The challenge was to install the hydraulic and mechanical equipment in confined spaces, while at the same time ensuring easy maintenance of the hose lines. We discussed and optimised all the tricky points together with the customer”, recalls Roland Bauer from the branch in Wels. And with success: the first Universal Tamper is already working on Deutsche Bahn tracks. The dense branch network of the system partner guarantees fast service, so it’s no surprise that further joint projects are already in the pipeline.

Learn more

- 12.03.2024

Drilling instead of digging

The horizontal drilling rigs from AT-Boretec work with hydraulicsFind out more - 12.03.2024

Gearing up for an underground attack

The Gotthard Tunnel: the building project of the centuryFind out more