Series production of pipelines and hose lines

Our central hose line series production facility in Bremen and the pipe bending centre in Schönebeck deliver tens of thousands of articles including ready-to-install high-pressure, PTFE and industrial hose lines, made-to-measure and in small or large batches, to OEMs every month. With us, you can expect excellent process reliability and compliance with quality standards. We also adapt our procedures in warehouse product management and logistics to suit your requirements.

Production in full flow

Processes perfectly synchronised for the optimum solution

The highest product quality and process reliability

We reliably maintain a consistently high quality even with large production volumes. The reason for this is our working processes, which are designed to work efficiently with one another and are optimised through a continuous improvement process (CIP). We also operate a quality management system that meets the highest standards. Working in our cleanroom, we ensure the technical cleanliness of hose lines, pipelines and other hydraulic components, even in large batch series production. By exercising this level of extreme care, we prevent the finest particles from contaminating hydraulic systems.

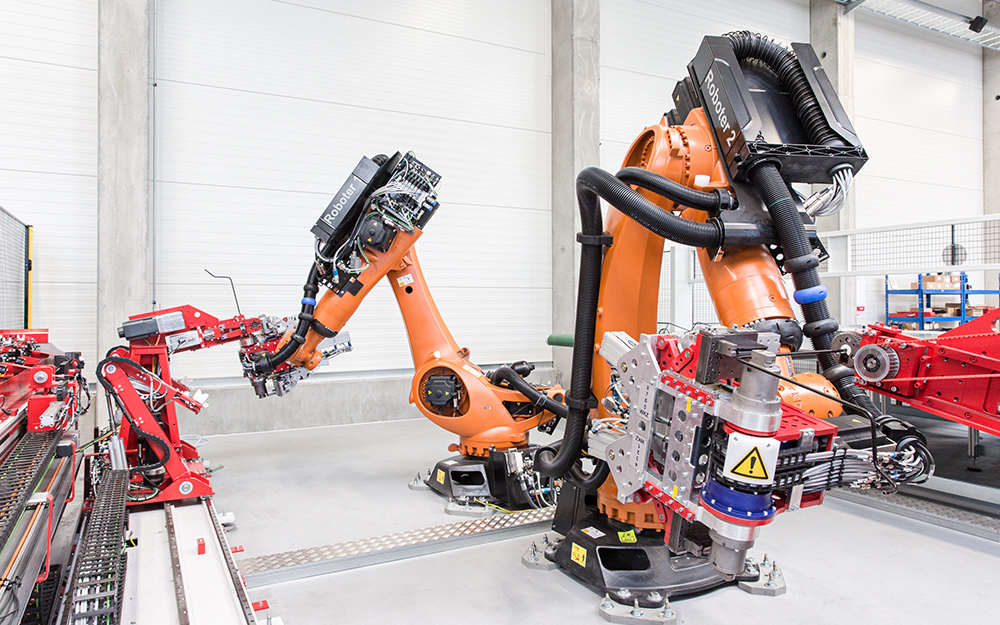

State-of-the-art production machinery and equipment

Our practice proven manufacturing processes run on state-of-the-art machinery and guarantees consistently high quality. Our range of machinery includes automated cutting machines, semi-automatic cleaning systems, hydraulic hose crimping machines with crimping dimension monitoring, CNC bending machines, fully automatic bending robots and orbital welding equipment. With these resources, we can manufacture hose lines in nominal diameters of 3 to 50 mm and precision pipe in diameters of 4.00 to 101.60 mm. With the ability to produce special fittings in-house, we can manufacture hose lines and pipelines precisely to meet your requirements.

Logistics support

As a system partner, we believe series production does not start in the production hall. We support our customers from design and development right up to product dispatch.

- Advice and design for component and component assemblies

- Manufacture of kits, component assemblies and hydraulic power units

- Delivery to your main warehouse or installation location

- Replenishment of ordered components in the kanban system

- Digital EDI interface for rapid order processing

Series production benefits

From the production floor to the dispatch department, our series production team provides an all-round service perfectly based on your needs.

Made-to-measure manufacturing

We preassemble hose lines and pipelines individually to meet the customer’s requirements

High process reliability

High process reliability allows us to achieve the proven HANSA‑FLEX quality in series production.

Delivery on schedule

State-of-the-art manufacturing methods ensure rapid availability and delivery on time.

Professional advice

We advise you extensively and implement the optimum solution in accordance with your requirements.

You can always rely on us

We supply you with high-quality hose lines and pipelines on schedule and in the quantities you wish.

Our series production facilities are designed so that we can supply traditional, medium-sized companies as well as industrial corporations as an OEM with pipelines on hose lines, ready to install and including customer-specific special fittings. Precisely synchronised processes, experienced staff and reliable quality inspections have already impressed many companies at home and abroad, including renowned manufacturers of rail transport and municipal vehicles, construction and agricultural machinery. We work with our customers to drive forward innovation and in this way improve the quality of the end product and the manufacturing parameters.

Behind the scenes

Gain an insight into our series production facilities and be impressed by the efficient workflows.

Our services portfolio in detail

- Quality

- Installation kits

- Efficiency

- Item 1

High quality standards

Our in-house quality assurance system ensures our processes are certified and maintain high quality standards. We can also perform customised inspections for you. TÜV-tested quality

- Compliance with all relevant standards such as DIN EN 853, 854, 856, 857

- Precise particle analyses at a microscopic scale

- In-house impulse test benches

- Cleanroom for monitoring technical cleanliness

- Preparation of inspection and test reports in accordance with VDA Volume 19, ISO 16232

- Item 1

Prepacked installation kits

All hose lines are supplied with fitting and sleeve and combined into a hose package. Your installation technicians can install the kit immediately without having to assemble the hose lines.

- Ready to install installation kits and component assemblies

- Unambiguous packaging

- Delivery Just-In-Time directly to the production line

- Delivery Just-In-Sequence through our branches

- Item 1

Efficient order processing

After receipt, orders are quickly checked and processed. We send you a cost estimate with a minimum purchasing quantity for the manufacture of your requested hose lines or pipelines.

- Transparent cost breakdown

- Demand can be displayed in real-time via EDI interface if required

- Computer-controlled stock and batch management

- Continuous improvement (CIP) reduces costs and increases quality

These topics may also be of interest to you

Works-in-works

Immediately available materials and components – that is the big advantage of the works-in-works manufacturing service from HANSA‑FLEX. The integrated manufacturing…

Find out moreKitting

As a system partner, HANSA‑FLEX provides ready-to-install kits containing components from third-party supplies as well as from HANSA‑FLEX. The production…

Find out moreKanban delivery

HANSA‑FLEX offers kanban delivery as part of an optimally configured, customised logistics system. Delivery based on the kanban principle is very…

Find out more